Zinc diecasting

Production and Machine Construction

- 22 fully automated die casting cells, in-house construction based on Frech, DAW 5 and DAW 20 machines

- 25 employees, annual capacity 1.5 billion parts

- Central automated surface treatment and separation

- Server-linked real-time machine monitoring with traceability

- Fully integrated ERP, digital networking of all processes

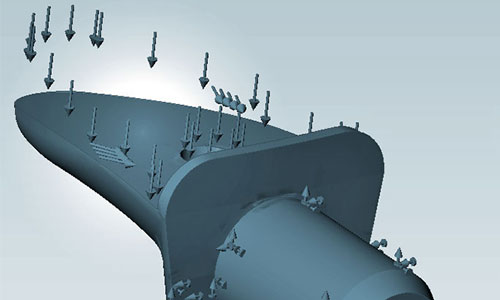

Design and Development

- 4 employees

- 3D CAD CAM workplaces networked with the mould-making

- Premise of development: optimized low cost production and high, reliable quality

- FEM calculation

Mould-making and Maintenance

- 10 employees

- Over 100 moulds per year

- 5-axis HSC milling centre with 5-axis CAM system

- All milling machining processes performed in-house

- Climatised mould-making shop and machines to meet high precision requirements

- Rapid Prototyping